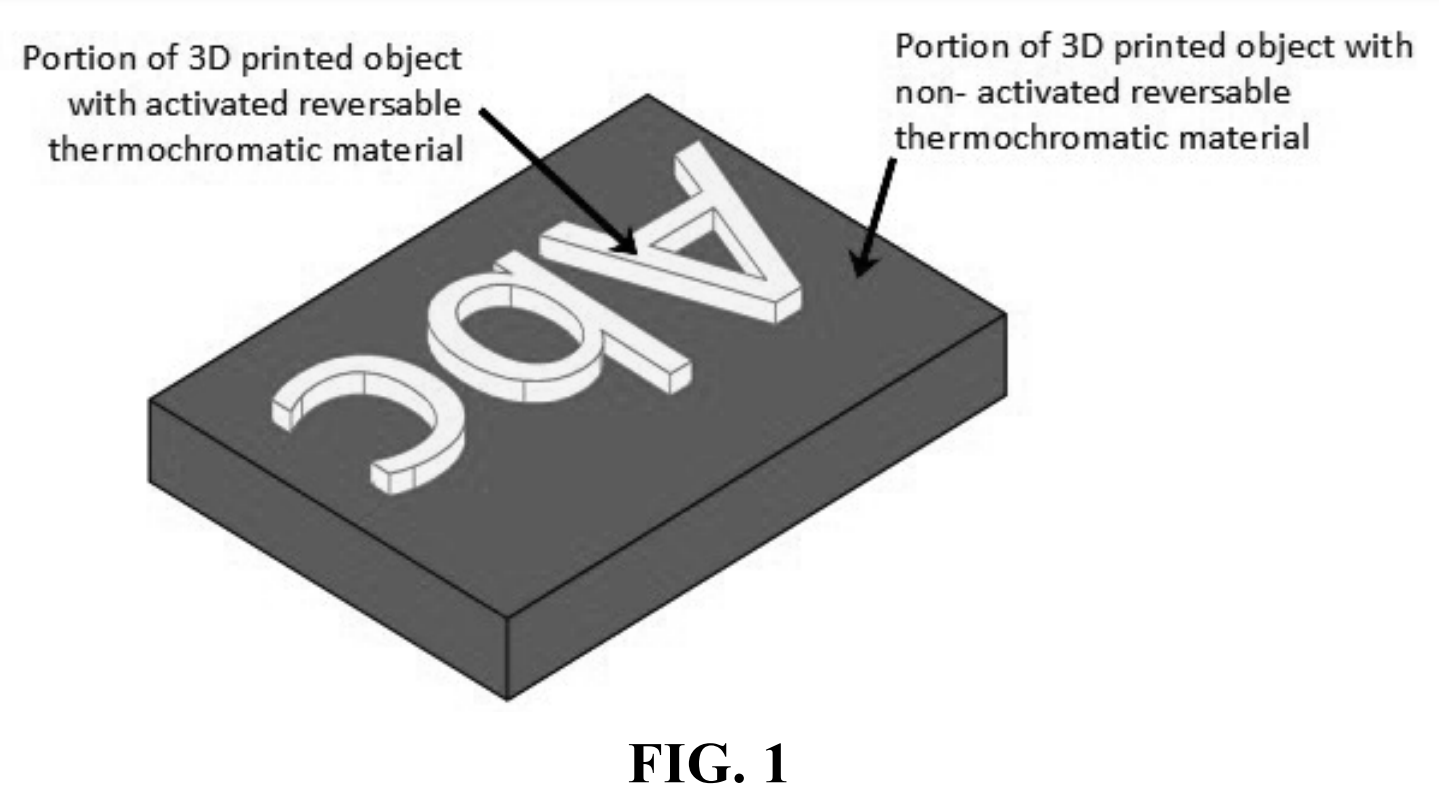

Multi-color 3d printing is hardImagine the possibilities for 3d printing multi-color objects using a stock 3d printer with no hardware modifications whatsoever. This might seem like a pipe dream but we are here today to explore this exciting development.

Today's options for multi-color printing require many modifications to machine hardware and software. Multiple print-heads / tool changes, manual human spool swaps or automated filament splicing machines are currently required to produce multi-color 3d printed objects. Autodrop3d's solution allows for software controlled color changes with stock 3d printers requiring no hardware modifications. |

What are reversible thermochromatic materials?Thermochromatic materials have special properties related to color and heat.

You might have seen mood rings before. That is an example of a material with thermochromatic properties. As the temperature of the material is changed the color is altered. This kind of thermochromatic material is not useful in 3d printing as it simply changes color based on the current temperature. Commercial LicencingAutodrop3d is looking for filament manufacturing partners to commercialize this patent pending technology. Please reach out discuss licencing.

|

How it works?

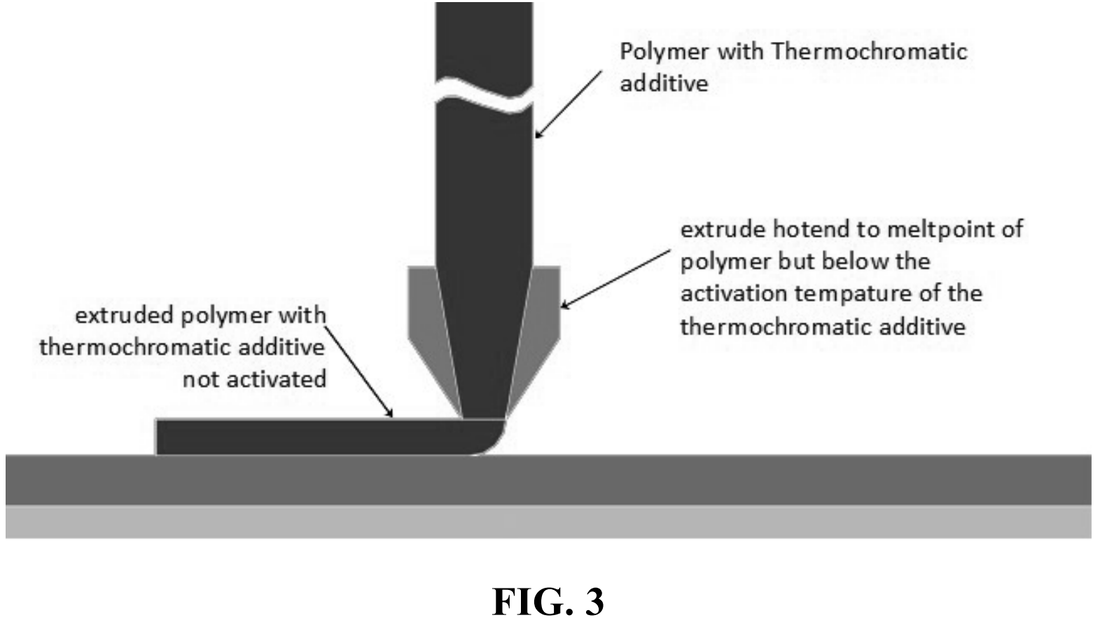

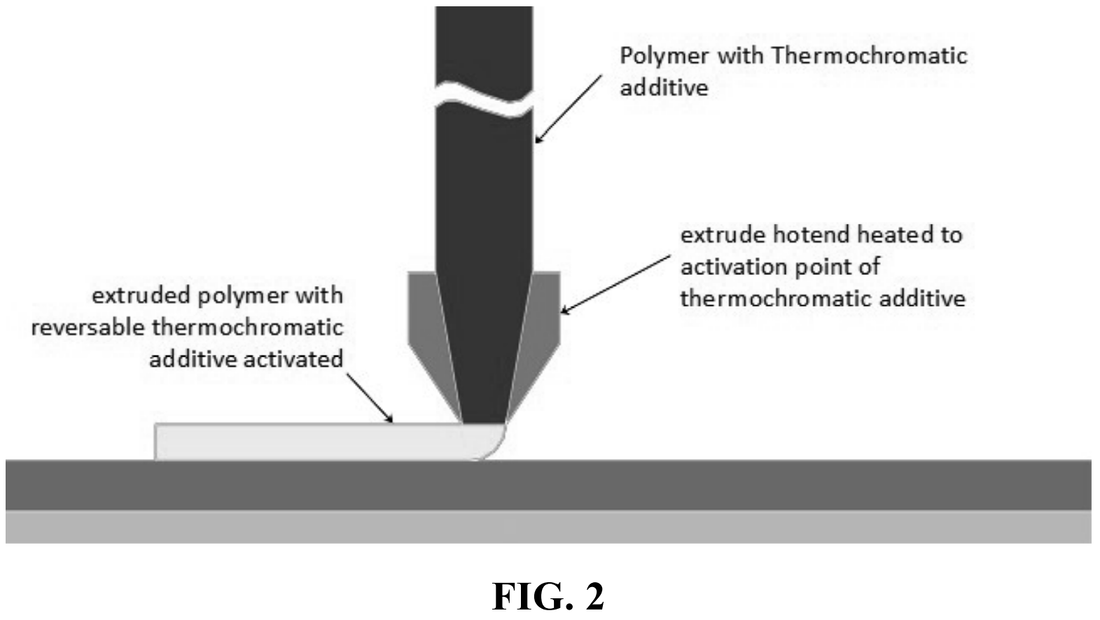

The magic of Autodrop3d patent pending approach to multi color printing is the ability to set the material color by altering the print temperature.

There are some thermochromatic materials that allow for the color to be set in a stable way allowing for a persistent change in color after the material is heated beyond a particular set point. An example of this property can be seen in erasable pen products. Erasable pens use heat generated by friction to make the ink transparent. To make the ink visible again all one has to do is freeze the paper and the color will be restored to the ink.

The thermochromatic materials we are using have two temperatures that trigger a color change. One is below freezing and the other is within the printable temperature of the particular plastic being used. This makes it possible to print the material and selectively change the color of portions of the print just by changing the temperature of the hot end.

There are some thermochromatic materials that allow for the color to be set in a stable way allowing for a persistent change in color after the material is heated beyond a particular set point. An example of this property can be seen in erasable pen products. Erasable pens use heat generated by friction to make the ink transparent. To make the ink visible again all one has to do is freeze the paper and the color will be restored to the ink.

The thermochromatic materials we are using have two temperatures that trigger a color change. One is below freezing and the other is within the printable temperature of the particular plastic being used. This makes it possible to print the material and selectively change the color of portions of the print just by changing the temperature of the hot end.

Proof of concept story

Mike Molinari with Autodrop3d was investigating the state of multi-color 3d printing and looking for a way to easily produce multi color prints on stock FDM printers. After looking and finding no good options available on the market that operated with out the need extra extruders, filament splicers, manual filament changes or servo driven permanent markers inspiration struck.

The print head temperature on FDM machines can be changed during the print and there exists materials that can have their color modified by heat.

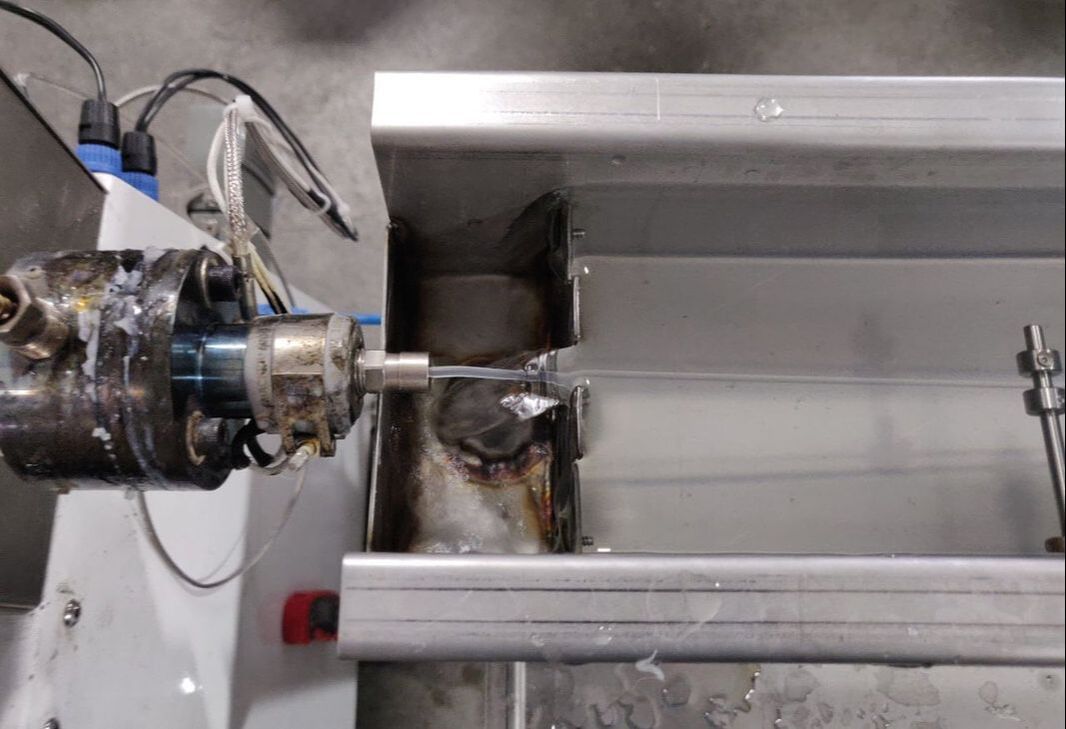

After much experimentation Mike was able to blend the color changing material in to a plastic polymer to demonstrate viability. Blending the color changing material in to the plastic polymer was the easy part but extruding filament is a complicated craft best left to experts. Making filament is as much an art as it is a science controlling speed, temperatures, tension, cooling and active tuning based on real time measurements of material diameters.

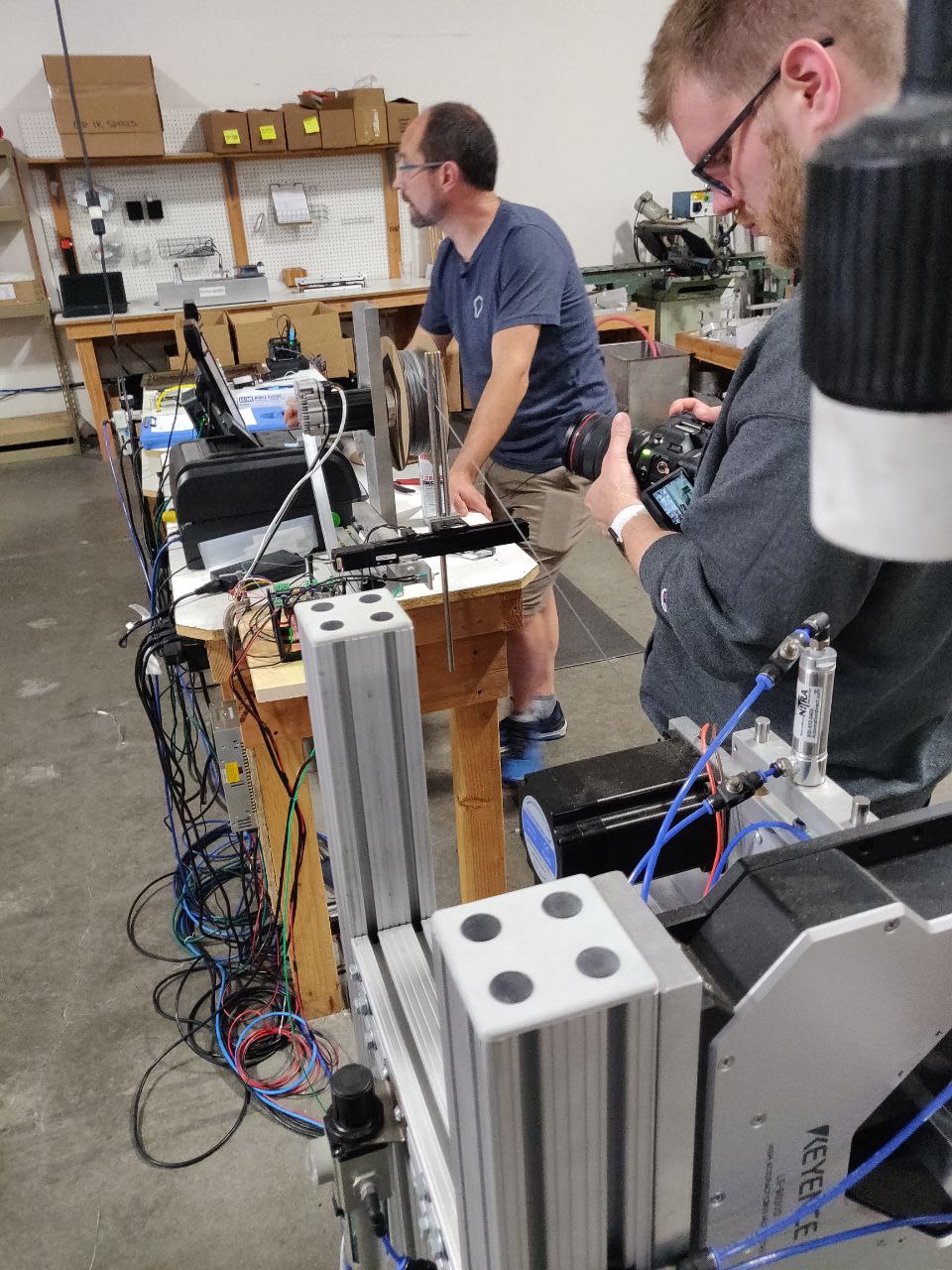

We reached out to Joel, the 3d printing nerd of youtube fame to see if he might be willing to try pushing our plastic through a filament extruding machine. Joel had a better idea and was able to connect us with the experts at Proto-pasta to bring the concept to reality.

Click here to see video documenting the manufacturing adventure and the results of the first proof of concept.

The print head temperature on FDM machines can be changed during the print and there exists materials that can have their color modified by heat.

After much experimentation Mike was able to blend the color changing material in to a plastic polymer to demonstrate viability. Blending the color changing material in to the plastic polymer was the easy part but extruding filament is a complicated craft best left to experts. Making filament is as much an art as it is a science controlling speed, temperatures, tension, cooling and active tuning based on real time measurements of material diameters.

We reached out to Joel, the 3d printing nerd of youtube fame to see if he might be willing to try pushing our plastic through a filament extruding machine. Joel had a better idea and was able to connect us with the experts at Proto-pasta to bring the concept to reality.

Click here to see video documenting the manufacturing adventure and the results of the first proof of concept.

Results of the first test

The results below show an object printed with 2 different temperatures for the 2 portions of the model. As you can see it worked and while the contrast between the transparent and colored portions is not very high it will only be a matter of testing different ratios of the color additive.